For all those curious how an inkjet printer works, keep reading. This is a practical explanation of what’s actually going on inside an inkjet printer.

An inkjet printer may have four, five, six, or more colors. It can print on postcards or 36 inch wide paper. However, no matter how big, small, or number of colors the inkjet process is basically the same.

The print head passes over the paper several times spraying tiny amounts of ink. Then the paper is advanced a little. The process is repeated until the image is printed.

The ink is designed to dry fast. Otherwise it would smear from handling it or the next page coming out of the inkjet printer. Of course, this also means ink can dry on the print head from inactivity. Which is why it’s a good idea to print a small test pattern once a week.

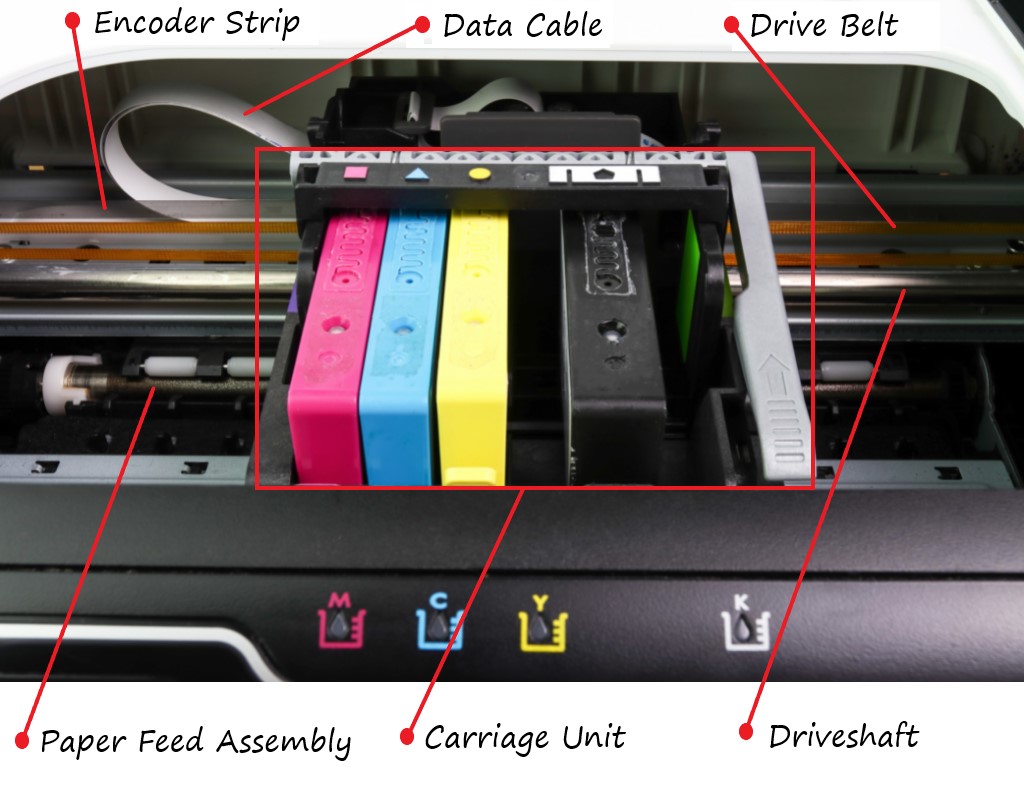

The Print Head

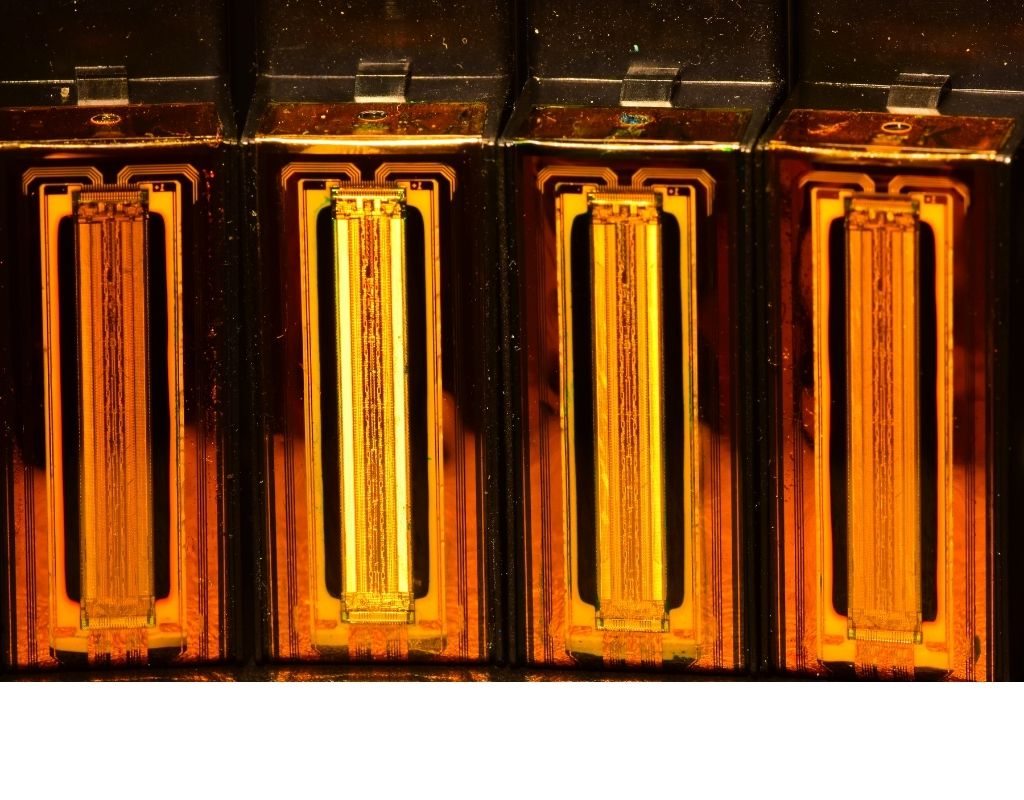

The print head is at the heart of how an inkjet printer works, so deserves a slightly expanded explanation. It is comprised of the ‘tank’ and the ‘print head’. The print head is basically a ribbon cable attached to the bottom of the cartridge with tiny holes in it.

It continues up the front or side of the cartridge and has contacts for the electrical connection. Molded in the plastic are small channels for the ink to flow from the tank to the print head. Inside the print head are anywhere from hundreds to thousands of holes depending on the printer. The more holes better and faster the output.

Surrounding each hole there are either tiny resistors or piezoelectric crystals. HP and Canon use resistors which uses heat to print. Epson and Brother use piezo type print heads which use mechanical energy to print.

Print heads with resistors use heat which causes the ink to boil. The phase change from a liquid to gas causes the ink to expand. This forces ink to take the path of least resistance out the hole (aka nozzle) and onto the paper.

Piezo type print heads have crystals which expand when activated. This hydraulically forces the liquid ink out the hole (nozzle) and onto the paper.

Whether a resistor or crystal is used, the amount of ink expelled is precisely controlled. The changes also happen repeatedly and rapidly since only a tiny amount of ink is involved. It takes several passes of spraying ink on the paper to get the desired density.

When a nozzle clogs it can leave light streaks in the image. Sometimes they can unclog and the streak will go away. Other times the resistor or crystal is damaged, causing a dead nozzle. Some inkjet printers will have a nozzle substitution utility. This can eliminate the streaks by having other parallel nozzles do double duty.

If you refill ink cartridges refill them before they are completely empty. In my experience this prevents damage to any nozzles. Also, empty print heads should be primed before use to avoid damage.

Noises and Nozzles

Some printers you can actually see the spray coming out the print head as it passes back and forth over the paper. This back and forth motion is the classic zip, zip, zip sound you hear as paper steps forward through the printer.

The cracking and popping noises you hear when the printing starts is the print head leaves the docking station and goes to the cleaning station. The docking or service station is where the inkjet printer keeps the print head when not in use. The service station locks the printhead in place when not in use and typically have a rubber seal to keep it from drying out.

The cleaning station, sometimes called a purging station or spittoon, is typically comprised of a white or yellow sponge to absorb excess ink and sometimes a wiper blade to clean the print head.

During a cleaning cycle the print head moves above an absorption pad then spray some ink. This flushes away any dried ink to clear the nozzles. Next the carriage unit moves over the wiper blade.

The wiper blade is made from rubber and wipes the print head clean as it passes by. Its similar to a windshield wiper for a car.

The service and cleaning stations can be at opposite ends of the carriage assembly (the metal rod the printhead moves on). On other inkjet printers the cleaning and docking stations are combined into one unit at one end.

Either way, it makes a lot of noise as the print head engages and disengages with these stations. Much like click pens or stereo cabinets, it only requires a back and forth motion to engage and disengage.

Inkjet printers use one motor for the carriage unit and one motor for paper feed. They have few electrical components such as clutches or solenoids. Instead rely on the the single plane movement of the carriage unit to accomplish many tasks.

Paper feed

Paper feed is accomplished by a set of small rubber rollers. Some printers substitute a pad instead of a roller to separate the paper. Their function is to take up one, and only one, sheet of paper from the stack, and feed it into the printer.

Just like tires on a car the tread will wear down over time and they will loose traction, which means jams. Even new tires on a car they can slip when there is excess gravel, or paper dust in the case of the printer.

The printer expects paper to activate a sensor after a certain amount of time of activating the rollers. If it seems the paper inexplicably just stopped, it’s probably because it took more than the allotted time to activate or deactivate a sensor.

It might only be a slight loss of traction on the paper but it’s enough to trigger a jam. If you do get a jam that’s hard to clear check out our guides to clearing printer jams.

Timing is also critical to align the paper with the print. An inkjet printer uses a thin strip of mylar to synchronize the print head with the paper. That encoder strip can get dirty over time from the ink over spray.

If that happens the printhead can become lost and make some very distorted prints. Or in rare cases crash into the end cap of the carriage unit.

Inkjet Summary

Overall there are few moving parts inside an inkjet printer. This doesn’t make them faster or last longer than a laser printer.

Even though a critical part (print head) for print quality is replaced fairly often. Print heads are sensitive components. They dry out, get dirty, and clog fairly easy. Inkjet printers do produce better color prints than a laser printer.

While the cost to produce an inkjet printer is low, ink cartridges are not very efficient. They wind up being a very expensive way to print thousands of pages.

Larger print volumes would require ink cartridges to be replaced every day. They are able to produce a high quality output but not good for large print volumes in my experience.

I hope this helps understand how the inkjet printer process works, what the normal noises are, and typical points of failure for an ink printer.

FAQ

Without ink an inkjet printer prints out blank pages.

Inkjet printers can’t handle more than 4,000 or 5,000 pages a month in my experience. Not only do they print slow but aren’t going to last much more than 50,000 pages.

Ink cartridges contain a reservoir of ink, channels for ink to flow to the print head, and a print head. Electrical signals are sent through the contacts to activate the print head. Which sprays out precise and controlled amounts of ink onto the paper.

Inkjet cartridges work by two methods.

Minute resistors surround each nozzle. When activated they cause a small amount of ink to boil. The phase change from a liquid to a gas causes it to expand. The path of least resistance in out the nozzle and onto the paper.

2, Minute piezoelectric crystals surround each nozzle. When activated they change shape and expand. The path of least resistance is out the nozzle and onto the paper.

Both methods send controlled and precise amounts of ink onto the paper to form an image.

The Copier Guy, aka Dave. I’ve worked on scanners, printers, copiers, and faxes over 26 years. When I’m not fixing them I’m writing about them. Although, I’m probably better at fixing them. I have certificates from Canon, Xerox. Ricoh, Kyocera, Lexmark, HP, and Konica Minolta. My experience includes other brands as well as several types of processes. If it uses paper I’ve probably worked on one.

Leave a Reply