When it comes to laser printers some may wonder what’s inside a laser printer. How they work is another topic. But If you’ve ever wanted to know what parts are inside a laser printer you’ve come to the right place.

You may have heard terms such as drum or toner associated with laser printers at some point. This article will go over each component inside a laser printer.

The main parts of a laser printer are:

- Toner

- Photoconductive drum

- Laser unit

- Fuser

- Developer unit (toner cartridge)

- Feed rollers

Toner

This is the main supply item for a laser printer. Toner is to a laser printer what ink is to an inkjet printer. It forms the image on paper.

It’s a dry powder designed for laser printers and isn’t compatible with an inkjet printer. It also is model specific, meaning you can’t put toner in just any laser printer. Each model of laser printer requires toner with a specific charge and melting point.

Toner is more durable than ink, meaning it doesn’t fade or run if it gets wet. However, ink generally produces better color print quality. One exception is professional grade laser printer.

While you can get ink for inkjet printers in a variety of colors, toner comes in four colors:

- Cyan

- Magenta

- Yellow

- Black

If you want to do heat transfers on dark t shirts special white toner is available. Toner can be used for heat transfers. Either printed on heat transfer vinyl (HTV) or a transfer sheet designed for laser printers. In my experience toner is extremely difficult to wash out of your clothes and that’s without heat.

Toner costs less than ink. Ink costs $1.79 per milliliter while toner costs $0.61 per gram. Which works out to $0.12 per page for ink and $0.12 per page for toner. If you printed 10,000 pages it would cost $1,200 with an inkjet printer and only $232 with a laser printer.

Drum

The drum is another supply item for a laser printer. It’s the heart of the electrostatic process. The drum essentially pulls toner from the developer to form an image then carries it to the paper.

If you look at a drum they are cylindrical in shape, made of aluminum, and have coating. Ones with a green coating use an organic material, thus the name: Organic Photoconductive drum (OPC Drum). If the drum has a brownish red or silver color it is an amorphous silicon (A-Si drum).

The main difference is A-Si drums last much longer since the coating is more durable. A-Si drums are also much more expensive than OPC drums. I’ve found OPC drums have slightly better text print quality.

OPC Drums can last from 20,000 to 500,000 pages depending on the model. A-Si drums can last from 100,000 to 1,500,000 pages depending on the model.

The cost and yield for OPC drums is lower so they are usually built into the toner cartridge. A-Si drums cost more and last longer so they tend to be individual units.

You’ll find OPC drums in most HP, Canon, or Ricoh laser printers. You can find A-Si drums in Kyocera Mita and Brother laser printers.

When a laser printer indicates the drum needs replaced, it’s because a specific amount of prints have been made. This doesn’t mean it has gone bad. It’s just the manufacturer determined after so many prints problems can appear with the drum.

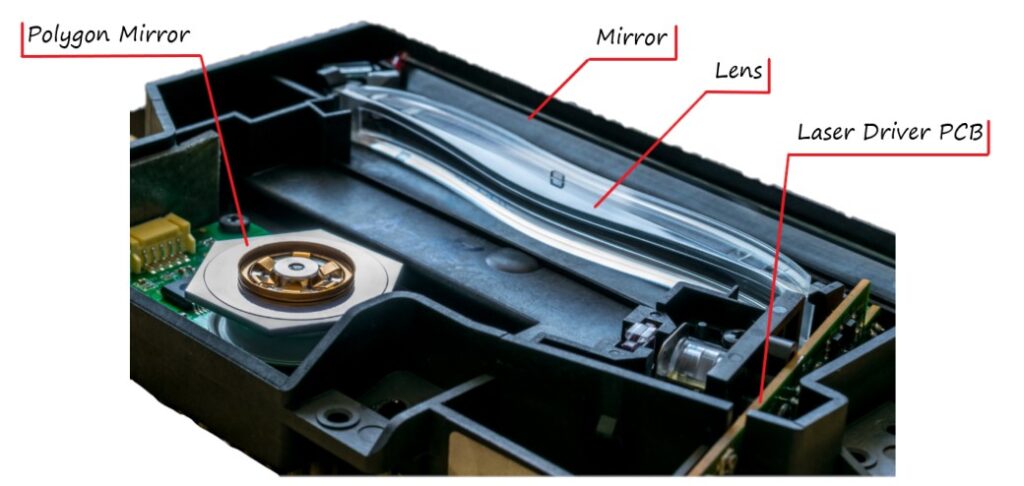

Laser

This is the unit which gives a laser printer its name. The laser unit writes an image to the drum with a class 1 laser.

It’s similar to ones used in laser light shows. The difference is only one color (red) diode is used in a laser printer. Also the mirror in a laser printer only spins on one axis and has multiple faces. Hexagon or octagon are the most common, but some have as few as 5 or as many as 12 faces.

The spinning mirror inside a laser printer is responsible for the high pitched noise you hear when it’s printing.

The laser unit generally last as long as the printer itself. Most are sealed units and don’t require any maintenance. On rare occasions I’ve had to clean toner dust from the reflective surfaces inside this unit. If dust gets inside the laser unit it causes light or faded prints.

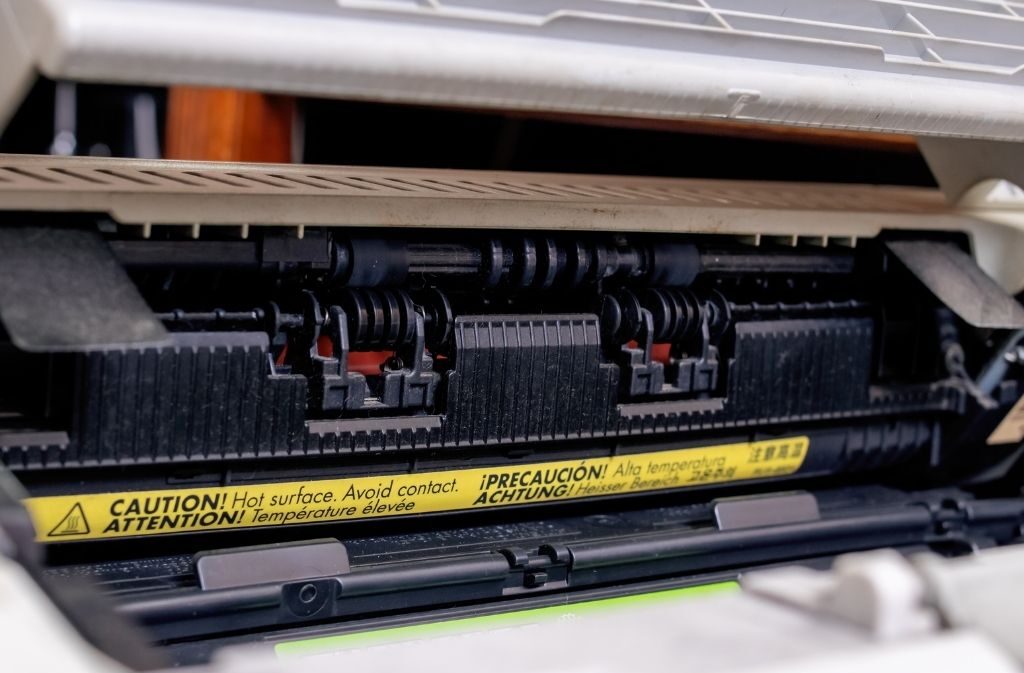

Fuser

A fuser is responsible for the heat and pressure that fuses the toner into the paper. There’s a heating element inside the top roller. You’ll find different heating elements depending on the model. They use a strip of resistors, a lamp, or induction type heating elements.

Most fusers optimal temperature is 190° C (374° F). Although, the operating range is from 180° C (356° F) to 210° (410° F). Which is enough to scorch your paper if it jams but not enough to catch fire. The flash point of paper is 233° C (451° F).

The top roller is either coated with a non stick Teflon surface or has a film of silicon. Paper and toner is inclined to stick to this roller. Which causes paper jams.

The coating eventually wears off or the film eventually cracks and peels. Once a fuser is worn out you will have to replace it.

If you have a small inexpensive laser printer you generally can’t replace the fuser. At least not without major disassembly. In most cases a new laser printer is less expensive than replacing the fuser.

Larger more expensive laser printers have replaceable fusers. Some require a tech but you can replace many yourself without any tools.

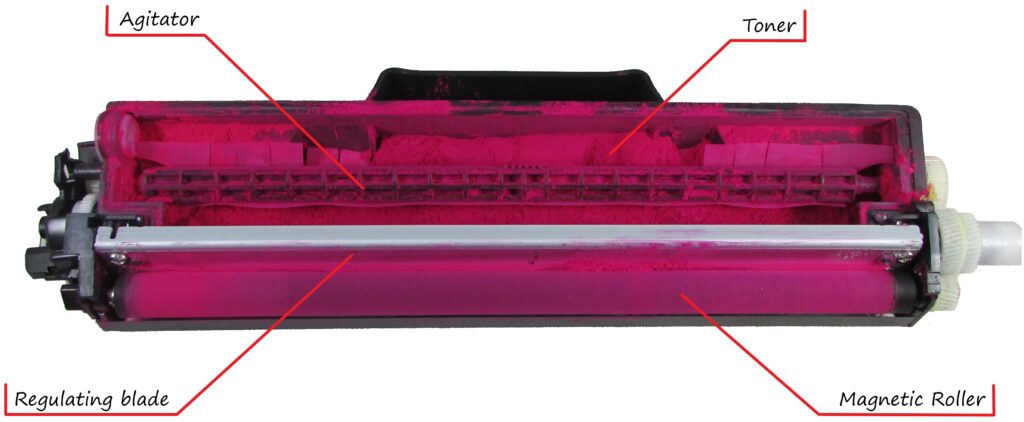

Developer

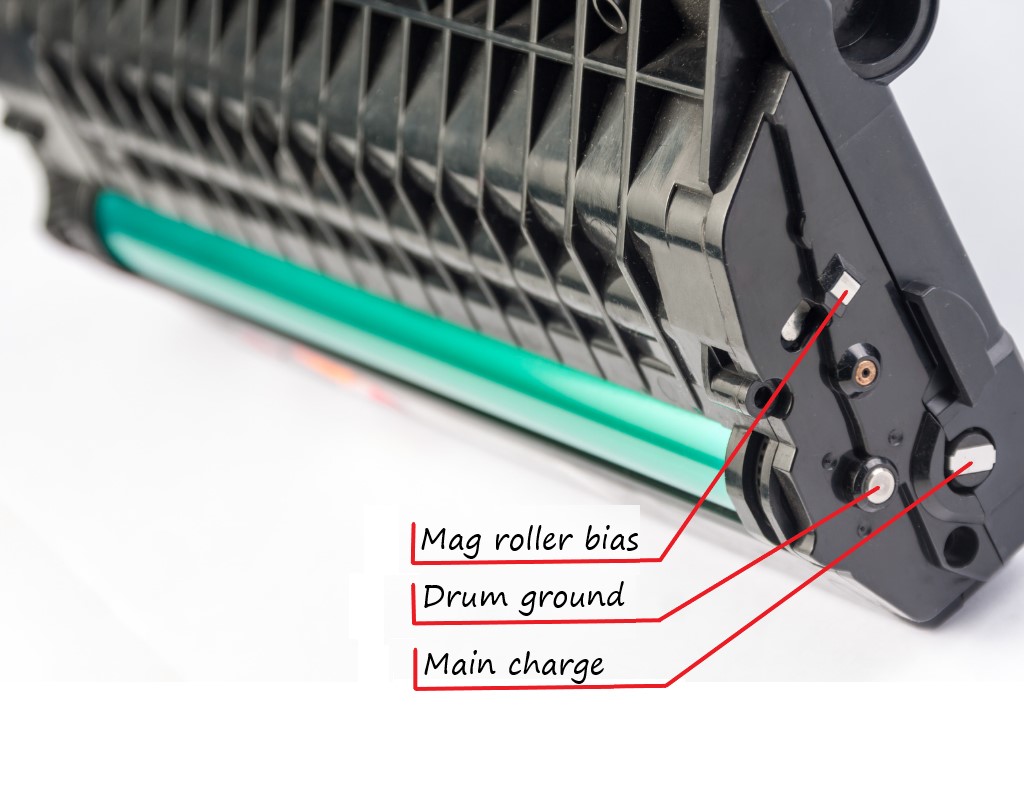

A developer is the part that houses the toner. The developer’s purpose is to continuously supply a uniform layer of toner to the drum.

The developer is responsible for generating a static and bias charge. Mixing the toner up generates a static charge and an A/C charge is applied to the magnetic roller.

The developer is usually built into most HP toner cartridge, as is the drum. Kyocera mita printers separate the components into individual units: toner cartridge, developer, and drum unit.

Once the developer runs out of toner you will get blank prints. Depending on the model it will need replaced or refilled by a separate toner cartridge.

Feed Rollers

You can find feed rollers inside any printer that uses paper. They are responsible for moving one sheet of paper at a time from the paper supply tray. Feed rollers are also used to move paper throughout its journey in a printer.

They also cause many paper jams. Like tires on a car once the tread wears out they will start slipping.

For smaller inexpensive printers these can’t be replaced without major disassembly. For other printers you can get replacement feed rollers. You can replace them without any tools or too much disassembly.

Summary

Those are the major parts found inside a laser printer.

FAQ

Toner is not the same as ink. However, it serves the same purpose as ink since it forms the image on paper.

You will get blank pages without toner from your laser printer.

Toner is a dry powder. The drum is a coated cylinder. They surface of the drum is where toner forms an image. Which is then transferred to the paper.

If you don’t replace the printer drum it won’t damage anything inside a laser printer. All printer drums will eventually develop streaks, lines, or faded print if you continue to use them beyond their recommended life.

Laser printers use a class 1 laser to create a latent image on a photosensitive drum.

Ghosting – where part of an image or text is repeated on prints is commonly caused by a bad fuser. Tracking, spots, clumps of toner, wrinkled paper, paper jams, and loud noises are all symptoms of a bad fuser.

A printer fuser is always near where the paper exits. For most laser printers this is in the rear.

The Copier Guy, aka Dave. I’ve worked on scanners, printers, copiers, and faxes over 26 years. When I’m not fixing them I’m writing about them. Although, I’m probably better at fixing them. I have certificates from Canon, Xerox. Ricoh, Kyocera, Lexmark, HP, and Konica Minolta. My experience includes other brands as well as several types of processes. If it uses paper I’ve probably worked on one.