If you’ve ever wondered how sublimation works then this is the right place to find out.

It’s easy to get started and hard to stop since you can get great results. Sublimation is a popular option for transferring designs. It’s much simpler than screen printing and has better results than iron on transfers.

While iron on transfers use heat transfer paper it is not the same process as sublimation. Iron-on vinyl (HTV) is another form of heat transfer. If you’ve used either of these then sublimation won’t seem too bizarre to you.

If you’ve used Cricut infusible ink then you are definitely be familiar with sublimation. Infusible ink also uses the process of sublimation.

Unlike other forms of heat transfers, dye sublimation ink is a permanent transfer. It won’t fade or come off due to the chemical reaction that takes place.

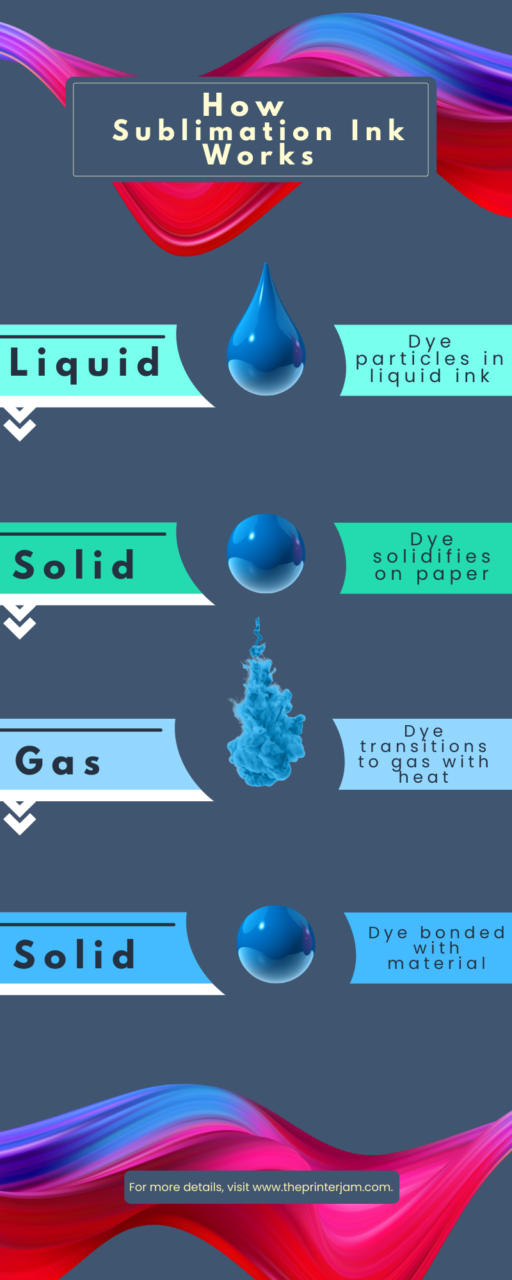

In simple terms, Sublimation is a chemical process where a solid transitions from a solid state to a gaseous state without going through a liquid state.

If you’ve seen dry ice (carbon dioxide) giving off fog then you’ve seen sublimation. As dry ice melts, it doesn’t turn into a liquid. Instead changes directly into a gas.

While sublimation ink starts as a liquid form it dries out on sublimation paper. Applying high temperatures to this solid form converts it into a gas. Dye in a gaseous state permeates the pores of the fabric.

Which forms a permanent bond on a molecular level with polyester fabric or rigid materials with a polymer coating. The most exciting upside to the dye sublimation process is your high quality designs won’t fade or peel after washing.

It’s an effective digital print method to create detailed designs on shirts, mugs, and many more items.

How You Can Do Sublimation

If you’re interested in doing sublimation then you’ll need the following items:

- Computer with a design program

- Sublimation printer

- Heat press or mug press

- Blanks

- Supplies (gloves, tape, paper, ink, etc)

The learning curve for sublimation is not steep. It didn’t take me long to get the hang of it. The start-up cost is negligible.

I already had a Brother and Epson printer so my biggest expense was a heat press machine. I’ve found heat presses are easier to operate than printers!

Blanks are your next biggest expense. The necessary supplies don’t add much to the overall expense.

Sublimation paper has the best results as a carrier compared to copy paper. But you can use copier paper, parchment paper, or butcher paper to protect your heat press and blank from blowout.

All told everything cost me less than $1,000 to get started.

Once you get the equipment, supplies, and blanks you’ll have everything you need to sublimate. But you’ll need some instructions. There are also many good tutorials on Youtube as well.

What Can You Sublimate On

Sublimation works on polyester fabric. It does not work on cotton shirts or other types of fabrics. You can use a blend of cotton and polyester fabric as long as it’s not less than 65% polyester.

In my experience when a 50-50 blend is used it has a faded or vintage look.

Sublimation usually produces bright, vibrant colors on fabric or rigid materials. The more polyester or polymer content the better the results.

Sublimation blanks are made of rigid materials as well. I’ve found the most common items are made of these materials:

- Ceramic

- Metal

- Plastic

- PVC

- Wood

You can sublimate on coffee mugs, keychains, signs, mouse pads, and decorations to name a few.

What Can’t You Sublimate On

You can’t sublimate directly on cotton shirts. If you want to sublimate on cotton, you have to first transfer a blank patch of heat transfer vinyl (HTV) on the cotton shirt. Then sublimate on the area of HTV which covers the cotton fabric.

You can’t usually sublimate on black t-shirts or other polyester fabric. Sublimation ink can only dye fabric darker, not lighter. So fabric that starts out black can’t be dyed.

Darker colored polyester fabric also has issues. Unless your sublimation prints are silhouette or greyscale art. In my experience, light blue polyester fabric is as dark of material as you should use.

Just about any rigid material that can survive a few minutes of 400°F is suitable for sublimation use. It can be coated with a polymer spray then it’s ready for sublimation.

How Sublimation Printing Works

Dye sublimation printing process is where a special printer loaded with special ink prints on sublimation paper. Which is finally transferred to special substrates.

This method of printing works the same as inkjet printing, only dye sublimation ink is used instead of regular ink. Any inkjet printer that is capable of using sublimation ink is a sublimation printer.

Unfortunately, your typical HP Envy and Canon Pixma printers cannot use sublimation ink. While HP and Canon do make expensive professional sublimation printers. In my experience Epson, Brother, and Sawgrass desktop printers make high-definition prints for sublimation use.

These are the items you need to make a sublimation printer work:

Sublimation printer

- Sublimation ink

- Sublimation paper

How Sublimation Ink Works

Dye sublimation ink looks and feels like standard ink. However, it contains a different type of dye. Sublimation ink is made of a disperse type dye with distinctive chemical properties.

Due to the disperse dyes chemical properties, it reacts with high temperatures (380-400°F/190-200°C) by changing into a gaseous state. As the ink cools the dye solidifies again forming a permanent bond on a molecular level.

Sublimation ink only works with polyester fabrics or polymer coated rigid items. The natural fibers of wood contain polymers which mean wood also works as a suitable substrate.

Sublimation ink uses the same 4 primary colors found in all subtractive color models to produce excellent results:

- Cyan

- Magenta

- Yellow

- Black

Inkjet printers use a number of colors of standard ink to make lab quality photos. Sublimation ink is intended heat transfers not lab quality photos.

The only additional colors of ink for this form of printing are fluorescent (neon) colors. All sublimation inks produce vibrant colors and great image quality for sublimation transfers.

Sublimation ink doesn’t work for regular printing since the end result on paper is very washed our or muted.

Summary

Sublimation printing is a process used and developed by professionals. However, you don’t need your own print shop to sublimate. You can get started with little investment and time.

Whether its home décor’ crafts, or resale sublimation is a great way to get a printed design onto polyester fabric or rigid materials in my opinion.

All in all it’s not hard and even beginners can get great results. Get yourself some t-shirts or tumblers and have fun!

FAQ

It works by applying heat to sublimation ink. As the heat melts the solid ink, it transitions into a gas instead of a liquid.

A sublimation printer or one capable of being converted. Sawgrass and Epson make sublimation printers. Epson and Brother inkjet printers can be converted. Then you just need sublimation ink and paper to do sublimation printing.

Not any printer can be used for sublimation. A laser printer can’t. Thermal type inkjet printers can’t. Only piezo type inkjet printers can be used for sublimation.

While sublimation is a form of heat transfer, it is superior to standard forms of heat transfer. Sublimation forms a permanent bond with the substrate.

The Copier Guy, aka Dave. I’ve worked on scanners, printers, copiers, and faxes over 23 years. When I’m not fixing them I’m writing about them. Although, I’m probably better at fixing them. I’ve worked with every major brand. As well as several types of processes. If it uses paper I’ve probably worked on one.